The Client

A leading industrial company in its segment that sought to improve the efficiency of one of its main production lines.

The Challenge

The company’s production line was facing a significant issue: a 23% Wall Thickness Excess, which resulted in 19% material over usage. This waste was a major source of hidden costs, draining the company’s profitability and leading to a potencial pérdida anual significativa. The lack of a clear, standardized procedure for setting the wall thickness was causing a high degree of process variability, and the company needed a solution that required no capital investment.

If you want to learn more about these problems, read our article on ‘5 Common Bottlenecks in Manufacturing and How to Spot Them‘.

The UpKaizen Solution

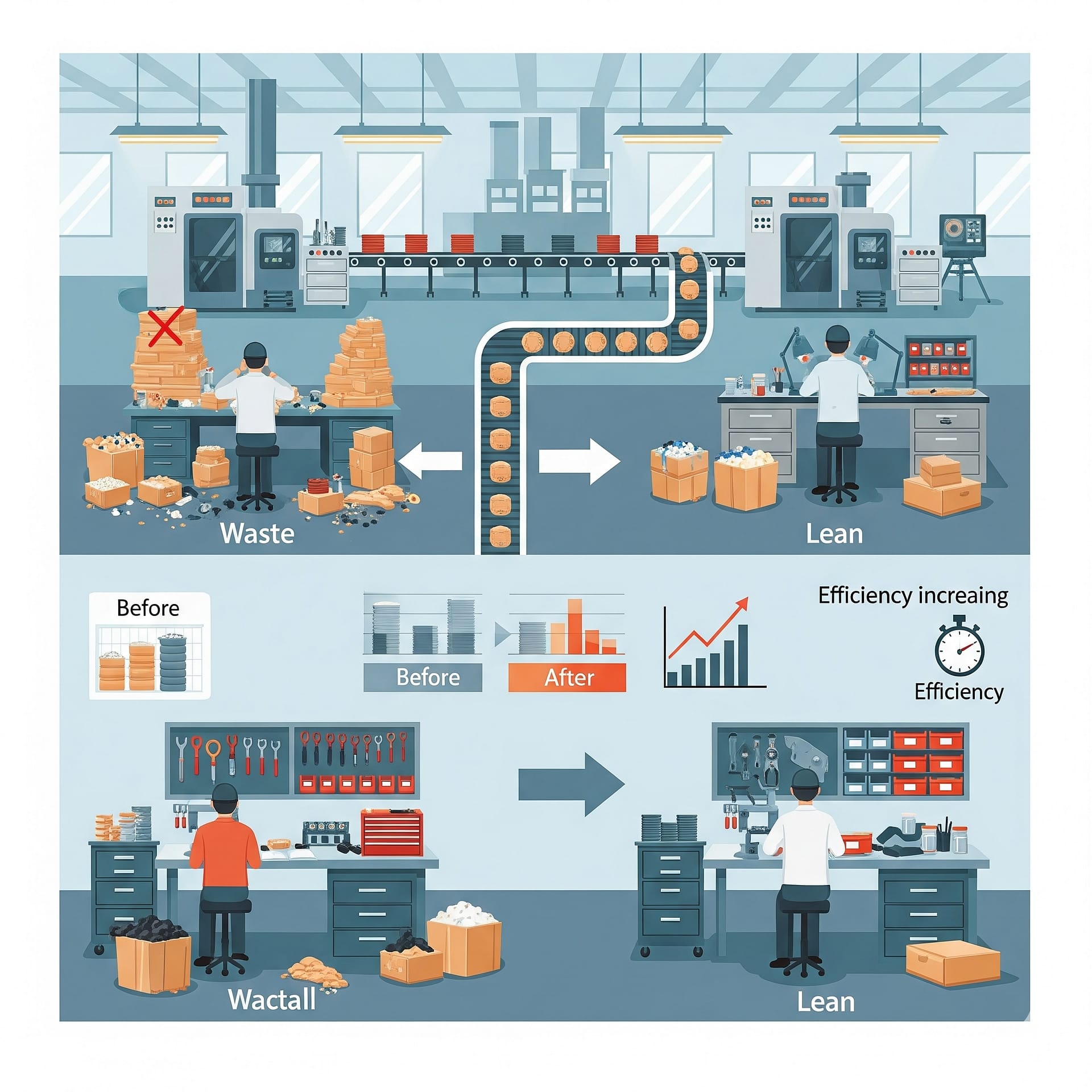

UpKaizen implemented a comprehensive, no-capital-investment methodology to solve the problem. The project, based on Lean Manufacturing and problem-solving tools, focused on Man, Method, and Measurement.

- Process Standardization: We defined clear and written SOPs (Standard Operating Procedures) for tool selection, machine settings, and measurement methodology.

- Root Cause Analysis: Using tools like 5 Whys and Ishikawa, we identified that the main problem was not the machinery but the lack of a standardized method.

- Training and Teamwork: We trained the operators on the new SOPs, focusing on the importance of standardization and process variability.

The Outcomes

The project delivered rapid and measurable results that far exceeded the client’s expectations:

- Significant Savings: The company achieved significant savings in just 8 weeks, reaching 96% of its savings target for the year.

- No Capital Investment: The entire project was implemented without a single euro of capital investment. The savings were achieved purely through methodology and process improvement.

- Improved Efficiency: The implementation of standardized procedures reduced process variability and improved the overall efficiency of the production line.

- Scaling the Solution: The methodology was so successful that the company planned to expand the system to its other production lines.

Do you identify with this case?

If your company suffers from high operational costs and a lack of process standardization, our Production Efficiency Micro-Diagnostic can help you find the solutions.

Not ready for a diagnostic? Join our newsletter