Introduction

Lean is a powerful philosophy for SMEs, not just large corporations. Its focus is on eliminating waste, maximizing value, and continuous improvement. This approach has a direct impact on costs and speed in both manufacturing and logistics.

What is Lean and Why Does It Matter for Your SME?

Traditional operations often suffer from “waste” (Muda). This waste can take many forms, including overproduction, waiting, transport, over-processing, inventory, motion, defects, and unused talent. Reducing this waste has a direct link to profitability.

Lean on the Shop Floor (Manufacturing)

Lean can transform a production line by using key tools such as 5S, Kaizen events, Standard Work, and Visual Management. The benefits of this approach include reduced lead times, improved quality, higher output, and a safer environment.

Lean in the Warehouse (Logistics)

Applying Lean to warehouse operations can involve using tools like layout optimization, efficient picking routes, inventory accuracy, and cross-docking. The results are faster order fulfillment, reduced inventory holding costs, improved space utilization, and fewer errors.

Bridging the Gap: From Shop Floor to Warehouse (End-to-End Efficiency)

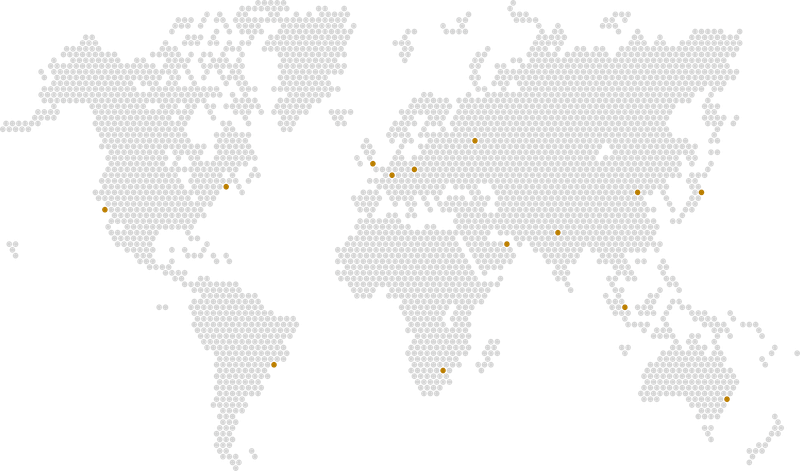

Lean thinking can connect the entire supply chain. The flow and communication between manufacturing and logistics are important. UpKaizen can help implement Lean across your entire operation.

Conclusion

Lean methodologies offer SMEs a clear path to operational excellence and tangible ROI. It requires both a mindset shift and practical application.

Ready to implement Lean and transform your operations?

Contact UpKaizen for a tailored assessment.

Subscribe To Our Newsletter

Join our community of like-minded Operational Excellence enthusiasts and subscribe to our newsletter for the latest trends, expert insights, and exclusive content delivered straight to your inbox. Let’s connect, explore and discover excellence in every step.