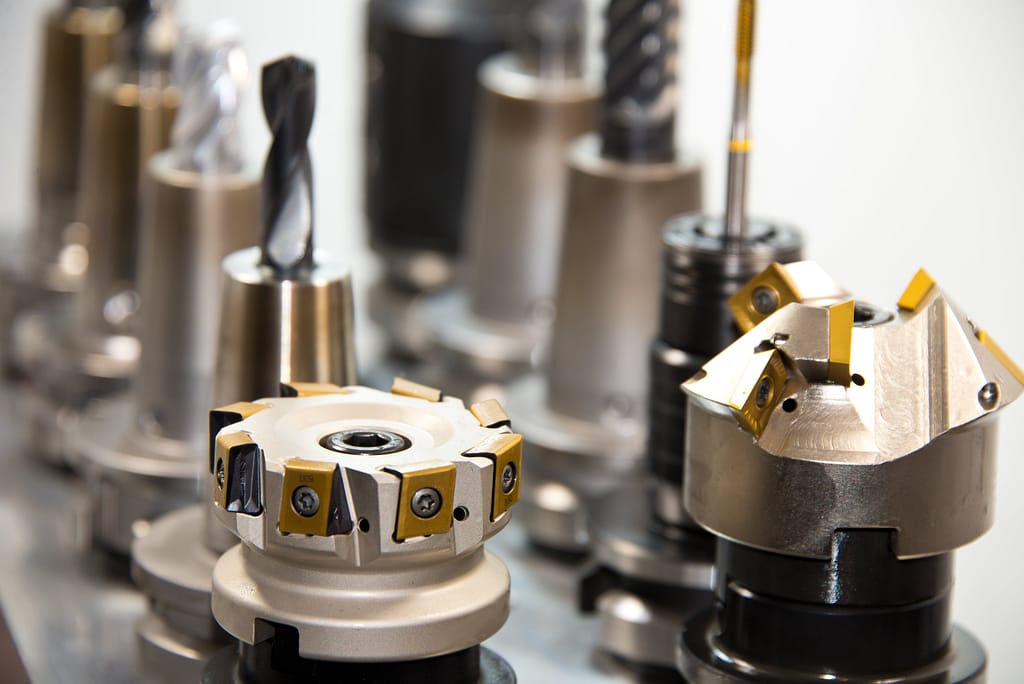

Case Study: Implementing a Spare Parts System for Enhanced Maintenance Management

The Client

A fast-paced manufacturing business seeking to enhance its competitiveness by modernizing its maintenance and inventory management processes.

The Challenge

The client was facing challenges in its maintenance management due to a manual, paper-based system for tracking spare parts. This led to costly inventory excess, frequent stockouts of critical parts, and a lack of real-time visibility into their stock levels. The company needed to transition to a digital solution to improve inventory accuracy, reduce costs, and support a more proactive approach to maintenance. If you want to know more about these types of problems, read our article on 5 Common Bottlenecks in Manufacturing and How to Spot Them.

The UpKaizen Solution

UpKaizen designed a comprehensive digital solution to meet the client’s needs. The system was completely redesigned to replace manual tracking methods with an integrated digital platform that provided:

- Real-time Inventory Tracking: A new system that gives the company real-time visibility into stock levels, reducing the risk of errors and delays.

- Enhanced Data Management: The platform eliminated the need for manual data entry, which significantly improved the accuracy of inventory records and provided the company with better insights into its costs.

- Proactive Maintenance Support: By ensuring the availability of critical spare parts, the new system laid the groundwork for a more proactive maintenance strategy, reducing unplanned downtime and enhancing operational efficiency.

The Outcomes

The implementation of the new digital system yielded significant outcomes for the client:

- Improved Inventory Accuracy: The transition to a paperless system led to a significant reduction in errors in inventory tracking, which helped the company reduce costs associated with stockouts and excess.

- Enhanced Operational Efficiency: The new system streamlined the process of managing stock levels, reducing the time spent on manual tracking and freeing up resources for other tasks.

- Cost Savings: By optimizing inventory investment and minimizing waste, the company was able to achieve significant cost savings in its operations.

- Enhanced Customer Service: The improved accuracy and real-time visibility into inventory led to better customer service capabilities, as the company could respond more quickly and accurately to customer inquiries and orders.

Do you identify with this case?

If your company suffers from a lack of data visibility or inefficient inventory management, our Production Efficiency Micro-Diagnostic can help you find the solutions.

Subscribe to our newsletter

Join our community of like-minded Operational Excellence enthusiasts and subscribe to our newsletter for the latest trends, expert insights, and exclusive content delivered straight to your inbox. Let’s connect, explore and discover excellence in every step.