In manufacturing, “rhetoric” won’t save you: what doesn’t modernize, becomes a museum piece.

Touring manufacturing plants across emerging markets is a constant reality check. We see two types of companies: those leaping into the future and those trapped in a paradigm that no longer exists.

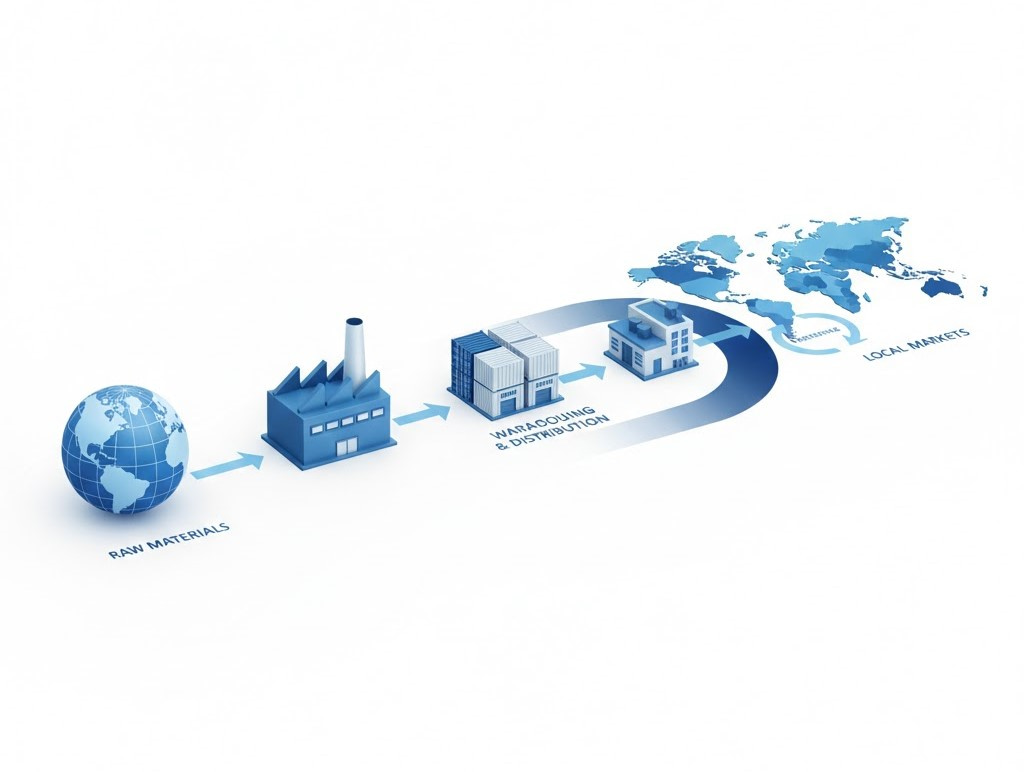

Operational excellence is not a destination, but a continuous cycle. At UpKaizen, we bridge the gap between traditional manufacturing and the 4.0 era by focusing on lean foundations before scaling technology. If your processes are broken, automation only speeds up the chaos.

The risk of falling behind isn’t just technical; it’s a matter of survival. Keeping obsolete processes in the hopes that “the context will improve” is a recipe for losing global competitiveness.

At upkaizen, we believe true transformation isn’t just about buying a machine—it’s about shifting the operational culture:

✅ Leaving old structures behind: The international market (especially under the new EU-Mercosur framework) has zero tolerance for inefficiency.

✅ Results, not promises: Shifting from “desktop diagnostics” to real-time execution at the “Gemba.”

✅ Purpose-driven automation: This isn’t about technology as a trend; it’s about efficiency with a measurable ROI.

If your plant is still operating like it did 20 years ago, you aren’t “preserving tradition”; you are managing obsolescence. In the 2026 landscape, only those who choose to evolve today will survive.

👇 Is your operation ready for the new global stage? Download our guide: https://upkaizen.com/revealed-the-5-silent-killers-that-kills-your-production/

Let’s discuss how to modernize your plant with no detours. 🗓️ Schedule a session with our Managing Director: https://meetings-eu1.hubspot.com/dante-garcia

#Industry40 #ManufacturingExcellence #Mercosur #UpKaizen #OperationalEfficiency #Kaizen #StrategicSourcing