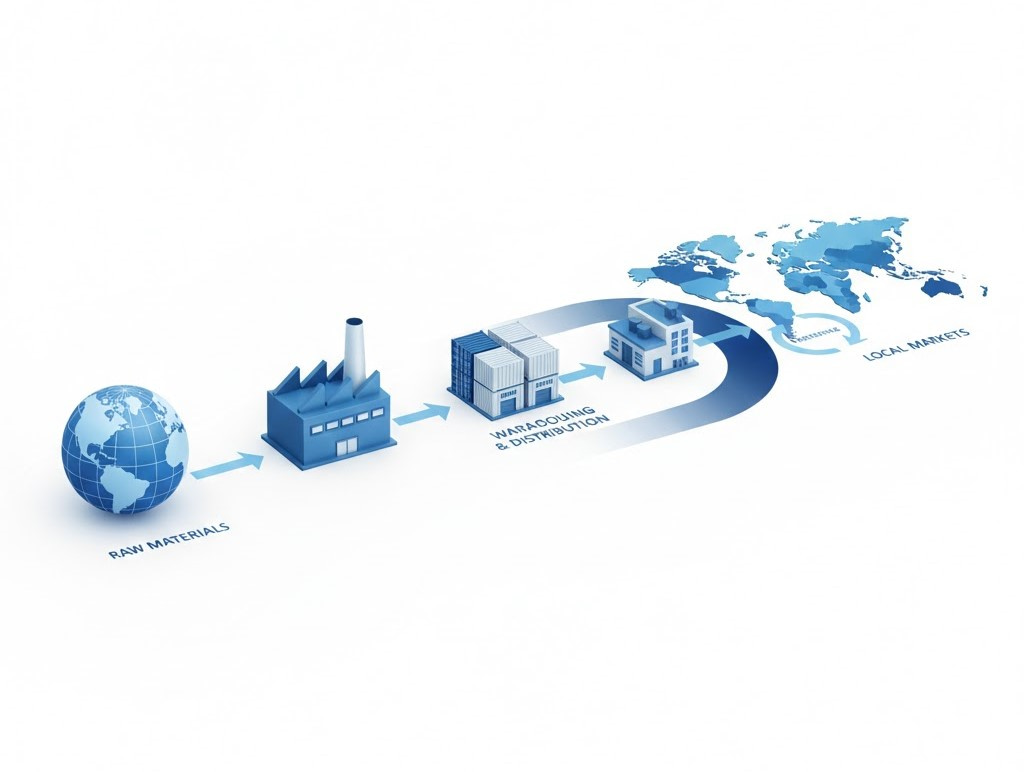

Why the Best Sourcing Strategies are Written in the Factory, Not the Office.

Last week, the EU-Mercosur agreement was signed, promising a revolution in industrial costs. But as I walked through a production line this week, I was reminded of a universal truth: A tariff reduction of 14% means nothing if your internal waste is 20%.

The “Dirty Boots” Philosophy

At UPKAIZEN, we don’t believe in remote sourcing. Strategic Global Sourcing requires a physical presence at the source. This week’s visit to [Tipo de Planta/Sector] focused on three critical pillars that no Zoom call can capture:

- True Capacity vs. Paper Capacity: Can the supplier actually scale to meet the new EU-Mercosur demand?

- Compliance at the Source: Seeing firsthand if the certifications match the floor operations (ESG, Safety, Quality Control).

- The “Kaizen” Culture: Is the supplier just a vendor, or do they have a mindset of continuous improvement?

Bridging the Gap

Operating between Switzerland, Germany, and the Mercosur block, I’ve seen that the biggest bottleneck isn’t the ocean—it’s the lack of technical alignment. My visit this week allowed us to:

- Identify 2 major bottlenecks in the packaging line.

- Synchronize logistical specs to avoid customs delays under the new treaty.

Next Steps for Your Operation

The new trade era is a race. The winners will be those who audit their supply chains physically and strategically.

👉 View our Strategic Sourcing Methodology

Not ready for a full Strategic Sourcing overhaul? Join the UPKAIZEN Newsletter