In the realm of manufacturing, efficiency is the golden ticket to success. That’s why our article dives deep into the world of Kaizen, offering proven strategies and handpicked tools to slash setup times and boost productivity.

Understanding Kaizen

Kaizen isn’t just a methodology; it’s a philosophy of continuous improvement deeply rooted in the Toyota Production System (TPS). At its core lies the belief that every organization harbors opportunities for change. By systematically addressing eight key wastes—including defects, overproduction, and unnecessary waiting—Kaizen aims to eliminate inefficiencies and drive perpetual improvement.

Kaizen Principles

Our article explores five foundational Kaizen principles, guiding readers to:

- Know Your Customer (KYC): By understanding customer needs, you can align production processes accordingly, minimizing waste and maximizing value.

- Embrace Seamless Flows: Allow processes to flow smoothly, minimizing interruptions and bottlenecks.

- Conduct Gemba Walks: Regular Gemba walks—direct observations of the workplace—empower employees to voice concerns and suggest improvements.

- Empower People: Foster a culture of empowerment, encouraging team members to take ownership of their work and contribute to continuous improvement.

- Practice Transparency: Open communication and transparency lay the groundwork for collaborative problem-solving and innovation.

Key Kaizen Tools

Delving into two powerful Kaizen tools, we spotlight:

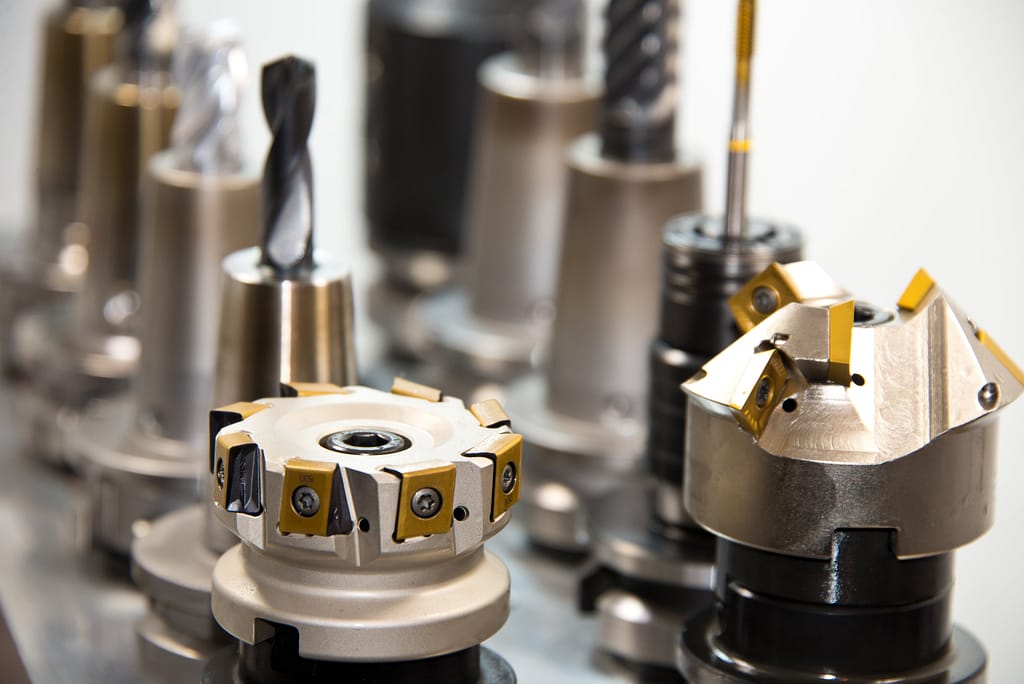

- Single Minute Exchange of Die (SMED): A game-changer in setup time reduction, SMED breaks down setup tasks into internal and external activities, streamlining processes and minimizing downtime.

- PDCA Cycles: Plan-Do-Check-Act cycles provide a structured framework for executing Kaizen strategies, driving continuous improvement, and enhancing lean manufacturing practices.

Achieving Continuous Improvement

Ultimately, the goal of Kaizen is to instill a culture of continuous improvement, delivering tangible benefits such as waste reduction, quality improvement, and increased productivity. By implementing Kaizen principles and leveraging key tools, businesses can unlock newfound efficiency and

Ready to revolutionize your manufacturing processes and drive sustainable growth?

Dive into our comprehensive guide to Kaizen methods and start your journey towards operational excellence today! Discover how our tailored operations management services can help you improve the operational performance of your organization.

Subscribe to our newsletter

Join our community of like-minded Operational Excellence enthusiasts and subscribe to our newsletter for the latest trends, expert insights, and exclusive content delivered straight to your inbox. Let’s connect, explore and discover excellence in every step.